Exploring the Advantages of DTG Printing for Your Apparel

In the world of custom apparel, the method of printing makes all the difference. Whether you're a fashion enthusiast or a business owner, the printing process not only affects the look of your designs but also their durability, comfort, and overall quality. One of the most advanced techniques revolutionizing the custom apparel industry is Direct-to-Garment (DTG) printing.

In this blog, we will dive deep into the advantages of DTG printing, compare it with traditional methods like heat transfer printing, and explain why it’s the perfect solution for achieving vibrant, long-lasting designs. We’ll also introduce the Brother GTX ProB, a cutting-edge DTG printer, and highlight how it elevates the printing process for superior results.

What is DTG Printing?

Direct-to-Garment (DTG) printing is a revolutionary technology that applies water-based inks directly onto fabric using specialized inkjet printers. Unlike traditional printing methods that rely on transfers or heat presses, DTG printers spray the ink in fine layers directly onto the fabric. This allows for intricate, high-resolution prints that can capture even the smallest details of your design.

One of the most significant advantages of DTG printing is its ability to print on-demand, making it a highly flexible option for custom and small-batch productions. The technique allows for vibrant, full-color designs that are seamlessly absorbed by the fabric, creating a smooth, natural finish that’s comfortable to wear.

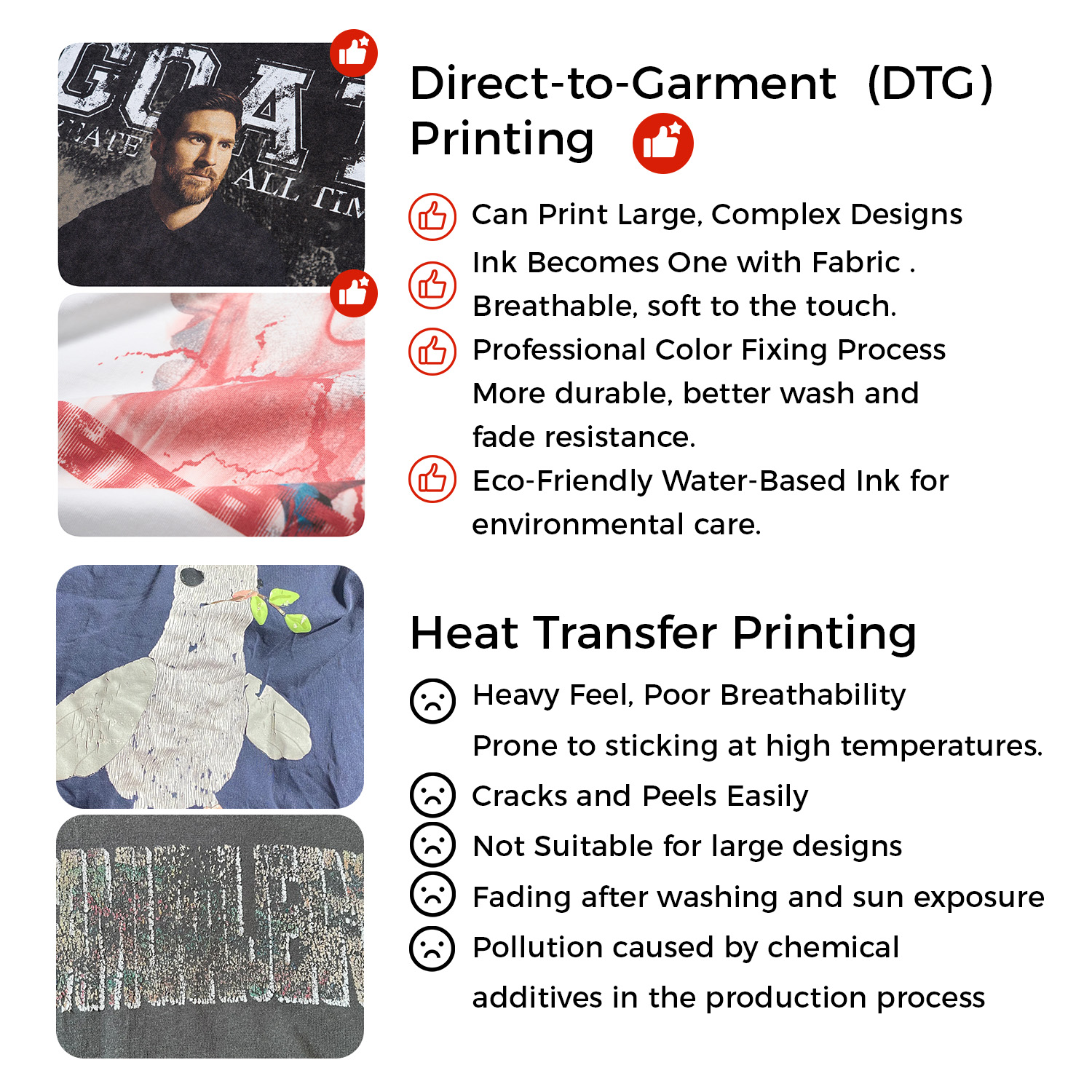

DTG vs. Traditional Heat Transfer Printing: A Side-by-Side Comparison

While heat transfer printing has been a standard method for custom designs, DTG printing offers a number of advantages that make it the superior choice for high-quality, long-lasting prints.

Heat Transfer Printing: The Conventional Approach

Heat transfer printing involves printing a design onto a special transfer paper and using heat to apply the design to the fabric. While this method is cost-effective, it comes with several drawbacks:

-

Heavy, Less Breathable Feel

Heat transfer prints can create a "plastic-like" finish, which not only feels stiff but also reduces the fabric's breathability. This makes the garment less comfortable to wear, especially for long periods. -

Cracking and Peeling Over Time

The longevity of heat transfer prints is often compromised. Over time, the design is prone to cracking, peeling, or fading, especially after multiple washes. -

Limited Design Complexity

Large or highly detailed designs can be difficult and expensive to print using heat transfer methods. The process struggles with intricate designs or photographic images, making it less versatile. -

Cost-Effective but Basic

While heat transfer printing is cheaper, it is a simpler and more basic option that doesn't offer the same level of quality or durability as DTG.

DTG Printing: The Modern Solution

In contrast, DTG printing brings several advanced benefits:

-

Perfect for Large, Complex Designs

DTG printing excels at handling detailed artwork, gradients, and complex designs. Unlike heat transfer printing, it can easily accommodate full-color, intricate patterns without compromising quality. -

Breathable and Soft Finish

Since the ink directly bonds with the fabric fibers, DTG prints feel soft to the touch and maintain the natural breathability of the fabric. There’s no heavy or "plastic" feel, ensuring maximum comfort. -

Enhanced Durability and Washability

One of the most significant benefits of DTG printing is its long-lasting durability. The inks used in DTG are specially formulated to resist fading, cracking, or peeling, even after repeated washes. Professional color fixation further ensures that the prints remain vibrant and intact over time. -

Higher Initial Cost but Superior Quality

While the initial cost of DTG printers and inks can be higher than heat transfer methods, the result is a much higher-quality, premium product that justifies the investment. For brands focusing on high-quality apparel, DTG is the clear choice.

The Brother GTX ProB: Setting the Standard for DTG Printing

One of the leading models in the DTG industry is the Brother GTX ProB. This printer represents the latest in DTG technology, offering incredible versatility, speed, and print quality.

All prints on our site are produced using the Brother GTX ProB printer, ensuring superior quality and precision.

Key Features and Advantages of the Brother GTX ProB:

-

Superior Print Quality

The Brother GTX ProB offers unmatched print quality with its advanced inkjet technology. It can reproduce fine details, gradients, and vibrant colors with outstanding precision, making it perfect for high-end fashion apparel and intricate designs. -

Faster Production Speed

With faster print speeds than many traditional DTG printers, the GTX ProB is ideal for on-demand printing and high-volume production. Whether you’re fulfilling bulk orders or offering custom designs, it ensures efficient and quick turnaround times. -

Wide Fabric Compatibility

The Brother GTX ProB is highly versatile and can print on a variety of fabric types, including cotton, polyester, and blends. This makes it a great choice for brands looking to offer a wide range of apparel options. -

Eco-Friendly Inks

The GTX ProB uses eco-friendly, water-based inks that are safer for both the environment and the end consumer. The inks are Oeko-Tex® certified, ensuring they are free from harmful substances, making them an ideal choice for eco-conscious brands. -

Long-Term Durability

Prints made with the Brother GTX ProB are not only vibrant but also incredibly durable. The ink bonds deeply with the fabric, maintaining its integrity even after extensive washing and wear.

By investing in the Brother GTX ProB, brands can ensure they are using the latest technology to deliver premium-quality prints that will stand the test of time.

The Quality of Our Fabrics: Perfect for DTG Printing

At our store, we pride ourselves on using only the highest-quality fabrics to complement our advanced DTG printing process. Each of our garments is carefully chosen to maximize the impact of your designs, ensuring crisp, vibrant prints that last.

Premium Cotton T-Shirts (280gsm)

Our standard T-shirts are made from 280gsm pure cotton, providing a soft, comfortable fit while being thick enough to prevent see-through. The fabric’s tight weave ensures durability, and it’s treated with a shrink-resistant process, so your T-shirt will maintain its shape after repeated washes.

Washed Collection

Our washed T-shirts and hoodies feature heavyweight pure cotton with a unique washed finish. This gives the fabric a soft, vintage look while maintaining excellent breathability and comfort. The fabric drapes beautifully, offering both a modern aesthetic and classic appeal.

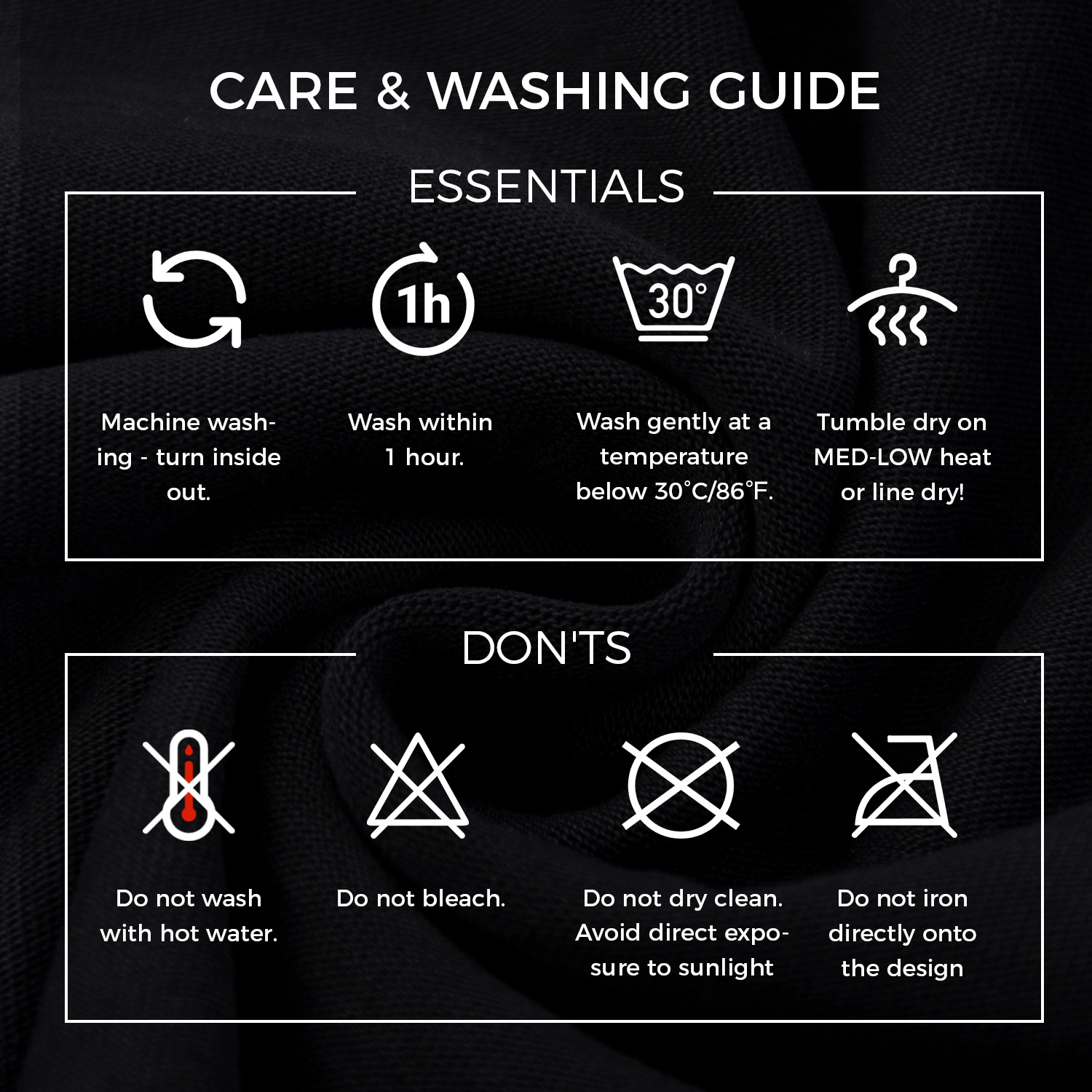

How to Care for DTG Prints

To ensure your DTG-printed garments remain in top condition, proper care is essential. Follow these simple steps:

-

Wash Inside Out

To protect the print, always wash your DTG-printed items inside out. This minimizes direct friction with other fabrics, keeping the design intact. -

Cold Wash

Use cold water to wash your garments, as hot water can cause fading and shrinkage over time. -

Avoid Harsh Chemicals

Steer clear of bleach or strong detergents that could damage the print or fabric. Gentle, mild detergents are the best option. -

Dry Low or Air Dry

While air drying is ideal, if you need to use a dryer, set it to low heat. High heat can damage the print and fabric.

Conclusion

DTG printing offers unmatched quality, precision, and longevity compared to traditional methods like heat transfer printing. It is the ideal solution for creating vibrant, intricate designs that stand the test of time. When combined with high-quality fabrics and cutting-edge equipment like the Brother GTX ProB, the results are truly exceptional.

For LFPspirit, who are committed to delivering high-quality, long-lasting custom apparel, DTG printing is the optimal solution. Embrace the future of apparel customization with DTG, and take your designs to an entirely new level!